Softgel Hardness Testing

Lab Methods & Capsule Hardness Tester

About Us

Softgel Hardness Testing

Softgel capsules are widely used in pharmaceuticals, nutraceuticals, and food supplements. Their popularity comes from easy swallowing, precise dosing, and excellent bioavailability. However, to guarantee quality, stability, and patient safety, manufacturers must control mechanical properties like hardness, elasticity, and rupture resistance. This is where softgel hardness testing becomes essential.

The hardness of a softgel is determined by its resistance to deformation under applied force. Factors like gelatin composition, plasticizer content, and environmental conditions during production significantly influence hardness. For instance, higher gelatin concentrations generally increase hardness but may reduce elasticity, affecting swallowability and dissolution rates.

The Science Behind Gelatin Capsule Hardness Tester

Importance of Softgel Hardness Testing

Softgel capsules are made of gelatin-based shells, often plasticized with glycerin or sorbitol. The mechanical performance of this material is influenced by moisture content, storage conditions, and formulation. Without testing, defects may only appear after distribution, leading to costly recalls.

Key reasons why softgel hardness testing is necessary:

01

Quality control

Ensures capsules meet defined specifications.

02

Process optimization

Helps fine-tune drying, plasticizer ratio, and encapsulation.

03

Regulatory compliance

Required for pharmaceutical approvals and audits.

04

Consumer safety

Prevents unexpected rupture or delayed release.

Gelatin Capsule Hardness Tester

Key Methods for Softgel Hardness Evaluation

Gelatin capsule hardness tester is designed to measure the force required to deform or rupture a capsule. Unlike traditional manual methods, automated instruments provide quantitative, repeatable, and accurate results.

1. Compression Testing (Distance mode)

The most common method, evaluates how far the capsule deforms under a specific force. A gelatin capsule hardness tester like Cell Instruments’ CHT-01 quantifies resistance, providing data on rupture strength and elasticity.

2. Bloom Strength Analysis

For gelatin-based softgels, bloom strength of soft gelatin capsules evaluates gel rigidity. Higher bloom values indicate firmer gels, critical for maintaining capsule shape under varying temperatures.

3. Rupture and Elasticity Testing

Softgel rupture testing identifies the force required to break a capsule, while softgel elasticity testing assesses recovery after deformation. Both metrics ensure capsules endure processing and transportation.

Gelatin Capsule Hardness Tester for Reliable Measurements

Advanced systems can perform different test modes, such as:

"Determines capsule resistance at a set pressure."

– Force measurement

"Identifies the maximum load before capsule failure."

– Peak rupture force

"Evaluates how far the capsule deforms under specific force."

– Distance mode

These features allow labs to analyze bloom strength of soft gelatin capsules and correlate shell integrity with formulation variables.

Bloom Test

Bloom Strength of Soft Gelatin Capsule

The bloom strength test is a traditional method used to characterize the gel matrix. It measures the firmness of a gel by pressing a plunger into the surface under controlled conditions. For softgel capsules, bloom strength directly relates to shell hardness, elasticity, and durability.

Monitoring bloom strength helps manufacturers adjust gelatin concentration, plasticizer ratio, and moisture level to achieve the desired capsule performance. When combined with hardness testing, bloom strength provides a comprehensive profile of softgel material quality.

Softgel rupture testing determines how much force is needed to break a capsule. This test is especially important for ensuring capsules remain intact during transport, blister packaging, and consumer handling.

Meanwhile, softgel elasticity testing evaluates how capsules deform under applied load. Elastic capsules are less likely to crack, but too much flexibility may cause deformation and sticking. By balancing elasticity and rupture resistance, manufacturers can ensure capsules meet both functional and regulatory standards.

Rupture & Elasticity Testing

Softgel Rupture Testing and Elasticity Testing

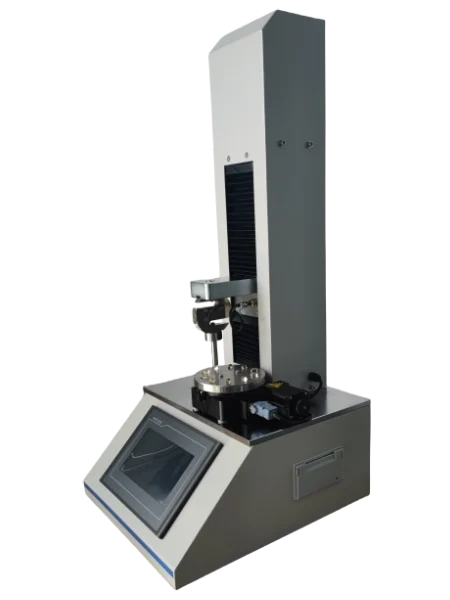

CHT-01 Softgel Capsule Hardness Tester

Softgel Capsule Hardness Tester from Cell Instruments

CHT-01 Softgel Capsule Hardness Tester

For laboratories and production environments that need reliable measurements, the Cell Instruments CHT-01 Capsule and Softgel Hardness Tester is an excellent choice.

Key advantages include:

- Multiple test modes (Force, Peak, Distance) for complete analysis.

- Rotating table for higher throughput and efficiency.

- Precision ball screw and stepper motor for smooth and accurate testing.

- Customizable fixtures to accommodate various capsule sizes and shapes.

- Automatic data recording and reporting with built-in microprinter and RS232 connectivity.

The CHT-01 is particularly valued for its durability, user-friendly interface, and compliance with quality standards, making it ideal for pharmaceutical and nutraceutical labs that demand precision.

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~300mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

"CHT-01 Capsule and Softgel Hardness Tester, a professional solution trusted by laboratories worldwide. By integrating reliable instruments into your workflow, you can strengthen quality control and build consumer trust."

– Cell Instruments

Frequently Asked Questions about Softgel Hardness Testing

1. Why is softgel hardness testing important in pharmaceuticals?

It ensures capsules have the right balance of firmness and flexibility, preventing rupture during packaging while maintaining proper dissolution.

2. What is bloom strength in soft gelatin capsules?

Bloom strength measures gelatin firmness and directly influences capsule shell hardness and elasticity.

3. How is softgel rupture testing performed?

Capsules are compressed until they break, and the peak force is recorded to evaluate rupture resistance.

4. What industries use softgel hardness testers?

Pharmaceutical, nutraceutical, food supplement, cosmetic, and research laboratories rely on hardness testers for quality control.

5. Can the CHT-01 tester handle different capsule sizes?

Yes, customizable fixtures accommodate various shapes and sizes.

6. How does elasticity affect softgel performance?

Elasticity impacts swallowability, dissolution, and resistance to damage.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985